Computer programs can be frustrating when they don’t let you do what you want. They are supposed to be a tool that helps you run your business! One complaint that I hear often from QuickBooks manufacturing users is that the program won’t let them build an assembly when they can see that they have the necessary parts on hand. Today we’ll look at a common cause for this problem.

Although QuickBooks lets you sell items that you don’t have (letting your on-hand inventory balance go negative), it won’t let you consume items that you don’t have in a build. If you want to build an assembly, you must have the parts, or it will mark the build as pending.

Timing is Everything…

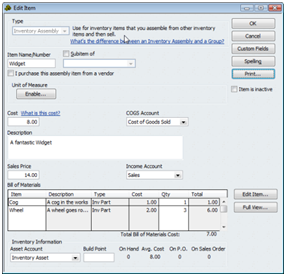

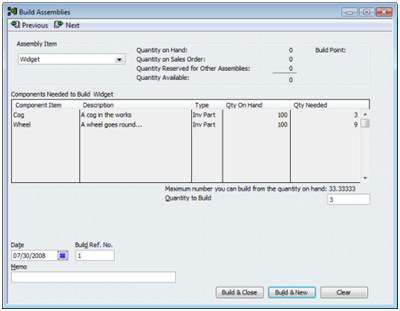

Let’s look at a simple assembly. My Widget requires a Cog and three Wheels.

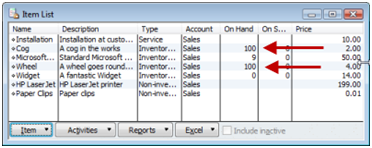

If I look at the Item List, I see that I have plenty of both on hand, so I should be able to make at least 33 Widgets.

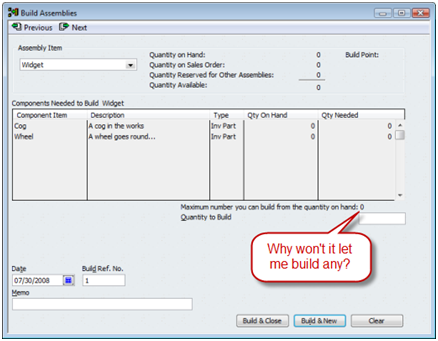

However, when I go to Build Assemblies to build my Widget, you can see that the program will not let me build any!

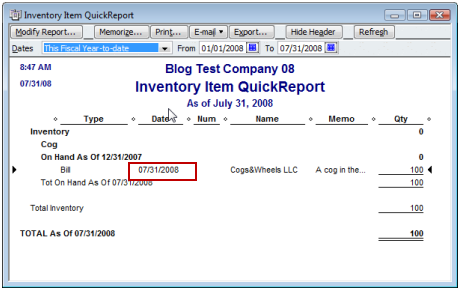

The key here is timing. In QuickBooks we have a great deal of flexibility when working with transactions. We aren’t forced to use today’s date – you can enter any date you wish. You can go back in time, you can even go into the future. Even though you have this flexibility, however, you are still constrained by time. The Item List doesn’t take the date into account. It shows you the sum of all transactions. Let’s look at a QuickReport for the Cog item:

Note the date of the bill? Now go back to the Build Assemblies screen shot I included before. See the build date in the lower left? It is 7/30/2008 – one day before the receipt. Builds are date sensitive – they see the inventory balance on the build date and in this case you haven’t received the items that you need to build.

This is a simple scenario, of course. In your business things are likely to be much more complicated. The principle holds true, though – inventory balances are date sensitive. It is easy to enter a transaction like a receipt with a wrong date. Perhaps the purchasing manager was behind on entering receipts and entered the current date when she caught up with the paperwork, rather than the actual date the items were received. Possibly the manufacturing foreman was entering several builds at a time, and the date carried over from the prior transaction that was entered so this date wasn’t correct. There are many reasons why dates and inventory balances can get out of synch.

In this particular case we can correct the problem either by changing the date of the receipt or the date of the build. Do not make an inventory adjustment to correct the balances, as that will just create more problems than are solved. Once you change either of the dates, the program will let you issue the build.

Changing Dates can create Pending Builds

You do have to be careful about changing dates of transactions, as you can create other problems this way. Fortunately, QuickBooks tends to give you warnings about some of these problems. You need to pay attention to these warnings and understand what the implications are.

Let’s take my example from above. We’ll correct the date on the receipt to make it 7/30/2008, so that we now can issue the build on that date.

After this, let’s say that someone entered another transaction in error, or went back and changed another date in a receipt transaction. Something that decreases the on hand balance on 7/30/2008. For example, that receipt could be deleted or changed to an older date. Or an inventory adjustment could be entered for an earlier date that decreases the quantity of inventory on hand on 7/30/2008. Is this a problem? We have already issued the build, so the parts have been consumed and I have my 3 Widgets in stock…

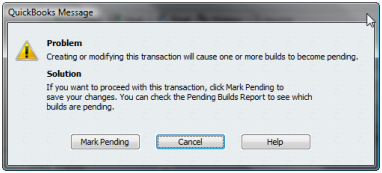

If I go back and delete that receipt I will get a warning:

By deleting the receipt, I don’t have the items I need to build the assembly on that date. QuickBooks is telling me that if I want to go ahead, it will mark the build as Pending. This also means that I won’t have those three Widgets in stock, so they aren’t available to a higher level assembly or for sale.

Nice article. I really wish QB would put the date at the top of the build form. I hate getting to the bottom, changing the date, then seeing there’s a problem.

In building an assembly I mix two liquids together in a 10 + 1 ratio. What I have when combined is 11. When I try to build however it dosen’t add them together. How do I adjust this?

Hi, PJ, thanks for the comment. QuickBooks isn’t entirely suited for this kind of manufacturing. However, the way to deal with this is that you need to set up the BOM to make one unit of the assembly. Let’s say it is gallons. You take 10 gallons of A and 1 gallon of B to make 11 gallons of mix. If you sell your mix by the gallon, you have to set the BOM up by gallon. One gallon of mix contains .90909 gallon of A and .0909 gallon of B. When you make one batch you issue a build for 11 gallons of mix. That will consume the appropriate amount of A and B, with a small rounding error (I think it uses .999 gallon of B in this case). That is how I would work with QB in this case.

Good article. I wonder why it can’t be more straight forward.

Infinitelyvirtual.com

This advice was invaluable! Thank you!

I purchased QuickBooks Pro 2009. I went to enter assemblies and see this is not an option in this version of the software. Are there any work arounds that you can give me to accomplish this? I build computers and need to account for the parts I use against my inventory. Any help would be much appreciated.

Mike, your only option is to either upgrade to Premier or play with “group” items. See this article for information on groups vs assemblies

Very good article. It’s too bad quickbooks’ help section can’t explain assemblies as articulately as you have here. They need you! I have 24 pending builds in my report yet I can’t find the assemblies to fix them. I hope you have an article on that.

Thank you.

I’m a bit confused by your statement about pending builds. What do you mean by “can’t find the assemblies to fix them”? The pending build report lists the builds, you can open the build and see what it is for, and what it needs…